Prepping a new generation of painting and decorating apprentices

25/03/04 6 min read

Read more

Learn about new product releases, special offers, industry news and more with the ProDec newsletter.

Our most commonly asked questions relating to this range. You can find a wider set of FAQs here or if you still have any questions about a specific product, feel free to contact us.

ProDec offers the most comprehensive range of products for the decorating trade, while ProDec Advance represents innovative products such as the Ice Fusion paint brush and roller collection, Titan roller frame and scraper, plus the Super Cling dust sheets. ProDec Contractor offers up a small range of entry point trade essentials.

It’s common sense that a tradesman’s everyday toolkit needs to cover the range of situations that your projects most often involve. Think also about preventing clogs and premature wear of abrasives, which will help maintain efficiency and ensure you achieve the right finish, as well as keeping your material costs down.

Abrasive papers:

Keep a core range of ProDec papers with your most commonly used grits for wood and drywall. Aluminium oxide is the trade’s go-to paper abrasive and ProDec has a wide range of grades. ProFlex takes ali oxide up a notch with crack-free cloth backing, which ups your productivity.

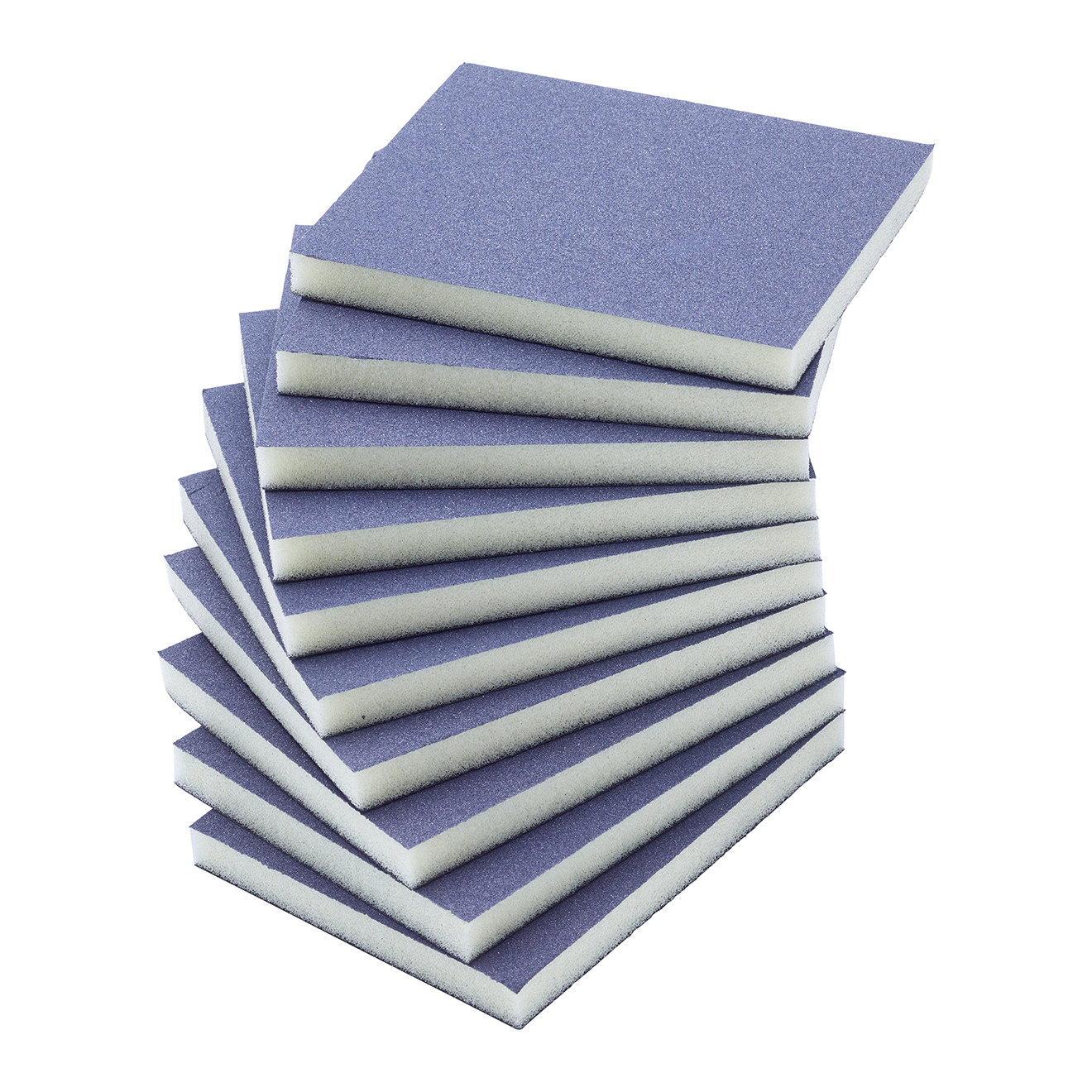

Sanding Sponges:

Flexible sponge abrasives are a godsend when it comes to sanding contoured surfaces effectively. They mould to the profile, ensuring that it’s sanded more efficiently than even paper abrasives, which can crack and lead to missed spots.

Steel Wool:

Steel wool is ideal for cleaning metal surfaces, with different grades depending on how tricky the task is, and ProDec’s fine steel wool is also useful for smoothing wood surfaces between finish coats.

Wire Brushes:

When heavy duty cleaning is required such as removing rust from metal surfaces, a steel wire brush is a useful tool. Consider one with a rake for when the going gets particularly tough.

Abrasives for Drywall:

Keep Sanding Mesh handy for finishing drywall surfaces. The mesh is ideal at preventing clogging, making for fast, efficient sanding.

Dust Extraction Equipment:

Consider using vacuums or dust extractors to minimise dust during sanding, promoting a cleaner work environment.

Tips for Preventing Clogs and Premature Wear:

Clean Abrasives Regularly:

Clogging reduces sanding efficiency and you’d be surprised how much extra life can be had from abrasive papers and sanding blocks through periodically cleaning them – especially aluminium oxide which has self-sharpening grains. Use a brush or specialised abrasive cleaning tools to remove debris.

Use the Right Grit:

Choosing the appropriate grit for each task avoids excessive wear on finer grades that aren’t up to heavier tasks, and on the other hand avoids over-abrasion from coarser grades where a finer one should be used. Starting with a coarser grit for material removal and rough surfaces and progressing to finer grits for finishing can extend the life of your abrasives.

Optimise Sanding Techniques:

Move the abrasive in the direction of the wood grain, apply even pressure and avoid excessive force. Proper technique minimises heat buildup through friction and reduces wear and if you’ve selected the right grade, the abrasive will do the work without tiring you out.

Dust Extraction Systems:

If you’re able, investing in quality dust extraction equipment to reduce dust accumulation from abrasives is something you’re unlikely to regret: it prevents premature wear, maintains efficiency and removes dust particles from the air.

Rotate Abrasives:

Rotate and flip sandpaper or abrasive pads during use to distribute wear evenly across the surface. Trade quality abrasive materials are distributed extremely consistently across the entire paper or pad, and using every square inch will give you maximum value for money.

Safety is of utmost importance when using abrasives, mainly because generating dust is what abrasives do. Here are some essential precautions that users should follow when using abrasives on a job:

Personal Protective Equipment (PPE):

Wear appropriate PPE, including safety glasses or goggles to protect your eyes from dust and debris – our sister brand Blackrock offers a full range.

Use a dust mask or respirator to avoid inhaling airborne particles and ensure it has a minimum rating of FFP2. Paying a little more for a mask with a valve will make breathing a whole lot easier which you’ll appreciate all the more if you have a lot of prep to do.

Wear hearing protection when operating power sanders to reduce the risk of hearing damage. Over the course of a career it can all add up and ear defenders are a very inexpensive price to pay to protect your hearing.

Protective Clothing:

Wear long sleeves, long trousers and gloves to protect your skin from abrasives and potential splinters. With prep being a significant part of many jobs, tradespeople often sand for extended periods and it can be rough on bare skin. Good gloves have breathable liners and will also improve your grip, reducing hand fatigue.

Consider using knee pads if working on surfaces close to the ground for extended periods. Wear and tear on knees all adds up over the course of a career and you’ll be thankful in later years for the investment you made in quality knee pads.

Ventilation:

Ensure proper ventilation in the work area to minimise dust buildup. Use exhaust fans or open windows to improve air circulation.

Dust Control:

Use dust extraction systems or vacuums to control and minimise airborne dust. If you’re able, investing in quality kit to reduce dust accumulation from abrasives is something you’re unlikely to regret.

Secure The Surface:

Every year, tradespeople have accidents that could be avoided by simply securing a surface properly to prevent it from moving unexpectedly during sanding, for example if you’ve taken a door off its hinges.

Power Tool Safety:

Follow the manufacturer’s guidelines for operating power sanders and other abrasive tools, especially when using for the first time. If you only read them once it’s better than not at all, and technology is constantly changing.

Disconnecting power tools when changing abrasive components avoids accidental starts which can lead to accidents.

Work Area Cleanup:

Keep the work area clean and free from clutter to prevent tripping hazards. Slips, trips and falls are the most common cause of workplace injury according to the HSE.

Dispose of used abrasives and other waste materials appropriately. We have a full range of Maintenance and Cleaning products here.

Emergency Preparedness:

Have a first aid kit on-site and know the location of emergency exits, especially if you’re working above the ground floor. Be prepared for potential accidents or injuries – even a small cut, nick or abrasion may require treatment and time will come sooner or later over the course of a career when even the most careful need a plaster.

Avoid Contact with Skin:

Minimise skin contact with abrasive materials. With prep being a significant part of many jobs, tradespeople often sand for extended periods and it can be rough on bare skin. Good gloves have breathable liners and will also improve your grip, reducing hand fatigue.

Proper Disposal:

Dispose of used abrasives and other waste materials in accordance with local regulations. Some abrasives may contain hazardous materials that require special handling.

ProDec products are sold by hundreds of retailers in thousands of stores, so you’ll never need to go too far to find them. Simply enter either your postcode, nearest town or city in the stockist finder and choose the distance you’re prepared to travel.

Owing to the number of products in the ProDec range, not all retailers will stock all our products so it’s worth contacting them before you visit. But if they don’t have what you want, all stockists are able to order any ProDec product and get it for you within a couple of days.

If you’re still struggling to find something, just give us a call, contact us through this form or email us at [email protected] and we’ll help you find it.

Please note that you can only buy from one of our stockists; we don’t deal directly with end users, for example professional decorators, builders, other tradesmen or DIYers.

ProDec products are sold by hundreds of retailers in thousands of stores, so you’ll never need to go too far to find them.

Use my location

Use my location

Apply to become a stockist today and discover the benefits of selling the ProDec range.

Become a stockist

25/03/04 6 min read

Read more

24/10/24 4 min read

Read more

24/10/12 3 min read

Read more

24/10/05 5 min read

Read more